Innova 5210 & 5010 Diagnostic Tools: A Comprehensive Guide

Innova offers clear instructions, simple controls, and immediate feedback for DIY car diagnostics, featuring large buttons and ergonomic design for easy, one-handed use.

Innova diagnostic scanners represent a leading brand in automotive diagnostic tools, empowering both professional mechanics and DIY enthusiasts to quickly identify and resolve vehicle issues. Recognized as America’s number one diagnostic tool brand, Innova prioritizes user-friendliness, offering devices with clear instructions, simple controls, and immediate feedback.

These scanners eliminate the complexities often associated with vehicle diagnostics, allowing users to handle car diagnostics independently. The design philosophy centers around accessibility, featuring ergonomic designs and large buttons for effortless operation, even with one hand. Innova distinguishes itself by minimizing setup hurdles; users can begin diagnostics immediately, without time-consuming account creations.

Comprehensive support resources, including detailed manuals, informative video tutorials, and active user forums, are readily available to guide users through the diagnostic process, ensuring a smooth and effective experience.

What is the Innova 5210?

The Innova 5210 is a best-selling diagnostic scanner, specifically renowned as a top-tier ABS code reader. As a flagship product from America’s number one diagnostic tool brand, it’s designed for ease of use, providing clear instructions and immediate feedback to simplify the vehicle diagnostic process. Its intuitive interface and simple controls make it accessible to both experienced mechanics and those new to automotive repair.

The 5210 boasts an ergonomic design coupled with large, easily-pressable buttons, facilitating comfortable, one-handed operation. A key benefit is its out-of-the-box functionality – no frustrating account setups are required before use. Innova supports users with readily available manuals, helpful video tutorials, and a vibrant community forum for assistance and shared knowledge.

This scanner empowers users to take control of their vehicle maintenance, offering a powerful yet user-friendly solution for diagnosing and resolving automotive issues.

What is the Innova 5010?

The Innova 5010 is a powerful diagnostic tool focused on efficient code retrieval procedures, as detailed within the Innova Electronics Knowledge Base. When utilizing the 5010, it’s crucial to always consult the vehicle’s service manual for comprehensive testing instructions. This ensures accurate diagnosis and avoids unnecessary part replacements based solely on Diagnostic Trouble Codes (DTCs).

The 5010 is designed to integrate seamlessly with Innova’s enhanced online learning platform, eSpired, providing a safe and secure environment for automotive education. This connection unlocks access to a wealth of resources, supporting both beginners and experienced users in understanding and resolving vehicle issues.

Furthermore, the 5010 benefits from Innova’s commitment to customer support and educational materials, fostering a confident and informed approach to vehicle maintenance and repair.

Key Features & Benefits

Innova scanners boast out-of-the-box functionality, eliminating time-consuming account setups and offering immediate usability with provided manuals and helpful video tutorials.

Ease of Use: Out-of-the-Box Functionality

Innova diagnostic tools are specifically designed for immediate use, prioritizing a user-friendly experience from the moment you open the box. Unlike many competitors, Innova eliminates the frustration of mandatory and time-consuming account setups. You can begin diagnosing vehicle issues right away, without needing to create profiles or navigate complex registration processes.

This commitment to simplicity extends to the scanner’s operation. Innova provides comprehensive manuals and readily accessible video tutorials to guide users through each step of the diagnostic process. Furthermore, a supportive online community forum is available for additional assistance and shared knowledge. This combination of straightforward hardware and accessible resources empowers both novice and experienced users to confidently tackle vehicle diagnostics independently, saving time and money.

Ergonomic Design & Large Buttons

Innova diagnostic scanners prioritize comfortable and intuitive handling. The design incorporates an ergonomic shape, allowing for a secure and natural grip, even during extended use. This thoughtful design minimizes hand fatigue and enhances control, making the diagnostic process more efficient and less cumbersome.

Complementing the ergonomic form are generously sized buttons. These large buttons are strategically placed for easy access and operation, even while wearing gloves or in dimly lit environments. This feature is particularly beneficial for mechanics or individuals working in less-than-ideal conditions. The combination of ergonomic design and large buttons ensures that Innova scanners are accessible and user-friendly for a wide range of users, promoting a seamless diagnostic experience.

ABS Code Reader Capabilities (Innova 5210)

The Innova 5210 distinguishes itself as a best-selling ABS code reader, providing users with the capability to diagnose issues within their vehicle’s Anti-lock Braking System. This functionality is crucial for maintaining vehicle safety and ensuring optimal braking performance. The 5210 doesn’t require complicated account setups or lengthy procedures; it’s designed for immediate use, offering a streamlined diagnostic experience right out of the box.

Users benefit from clear instructions and simple controls, allowing for self-diagnosis of ABS-related problems. This empowers vehicle owners and enthusiasts to address potential issues proactively, potentially saving on costly repairs. Access to comprehensive resources, including manuals and video tutorials, further supports the user in understanding and resolving ABS-related diagnostic trouble codes (DTCs). The Innova 5210 delivers professional-level ABS diagnostics in an accessible package.

Using Your Innova Scanner

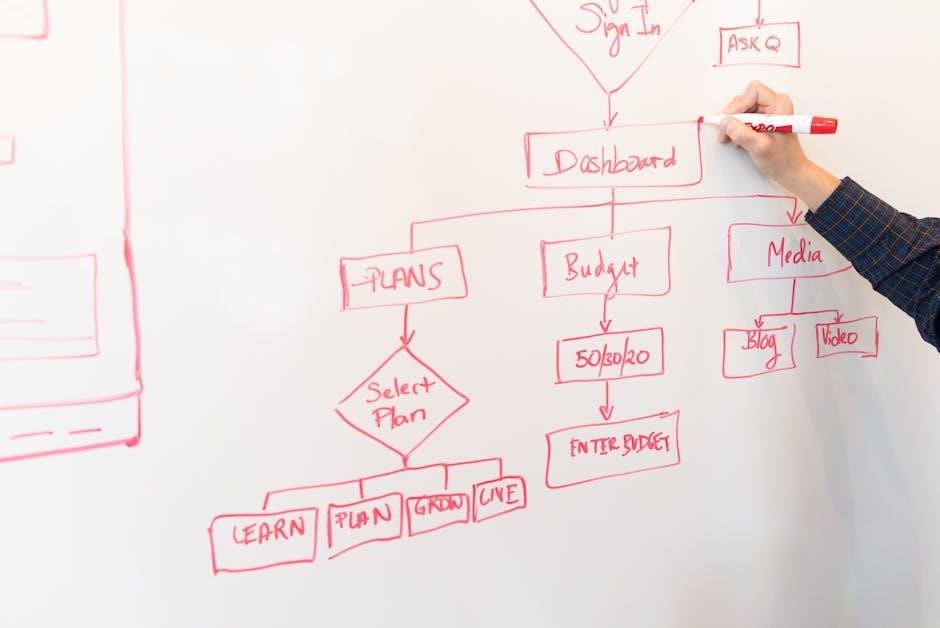

Innova scanners facilitate code retrieval, always referencing the vehicle’s service manual for detailed testing instructions before replacing any parts based on DTCs.

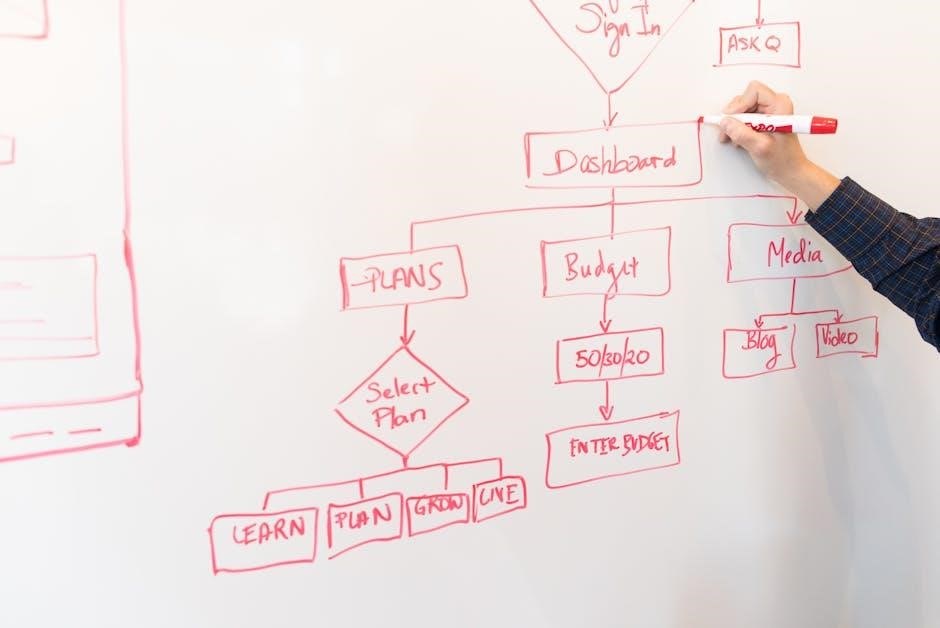

Code Retrieval Procedures

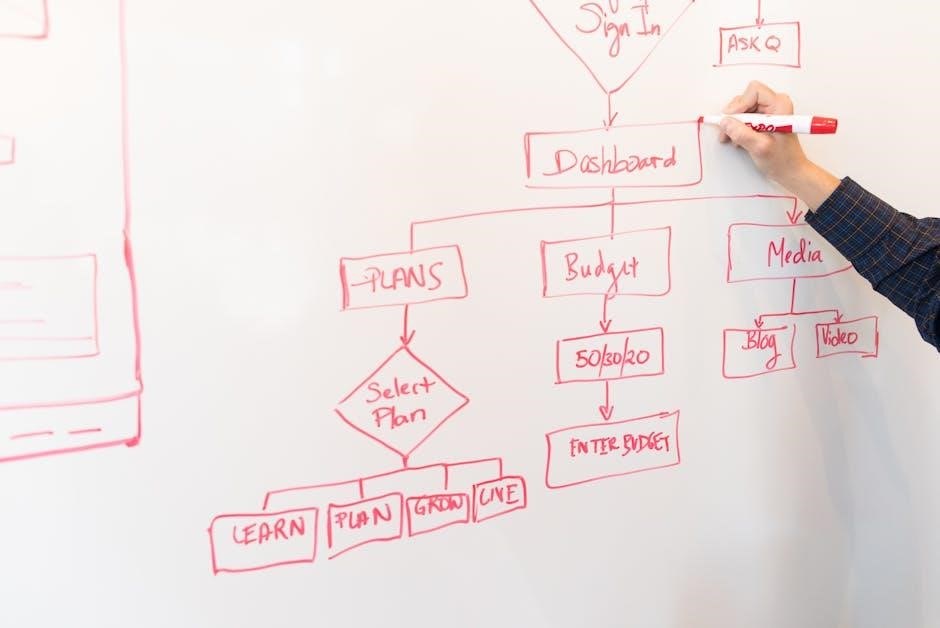

Innova emphasizes the importance of consulting your vehicle’s service manual for comprehensive testing procedures when retrieving codes. This ensures accurate diagnostics and avoids unnecessary part replacements solely based on Diagnostic Trouble Codes (DTCs). The process begins with connecting the Innova scanner to the vehicle’s OBD-II port, typically located under the dashboard.

Follow the scanner’s on-screen prompts to initiate the code reading process. The scanner will then display any stored DTCs, providing a starting point for identifying potential issues. Remember, a DTC indicates a potential problem area, not necessarily a faulty component. Always verify the code with further testing as outlined in the vehicle’s service manual. Innova’s resources, including online manuals and video tutorials, can further assist in understanding these procedures and interpreting the retrieved codes effectively.

Referencing Vehicle Service Manuals

Innova consistently stresses the critical role of vehicle service manuals throughout the diagnostic process. These manuals provide detailed, vehicle-specific testing instructions essential for accurate troubleshooting. Relying solely on DTCs can lead to misdiagnosis and unnecessary repairs; the manual offers context and proper verification steps.

A service manual outlines the correct procedures for testing components related to a specific DTC, including voltage checks, resistance measurements, and visual inspections. It details the manufacturer’s recommended methods for confirming a fault and identifying the root cause. Innova’s tools are designed to complement, not replace, the information found within these manuals. Utilizing both resources empowers users to perform informed and effective vehicle diagnostics, ensuring repairs are targeted and reliable.

Understanding DTCs (Diagnostic Trouble Codes)

Innova diagnostic scanners retrieve valuable DTCs, but interpreting them correctly is paramount. A DTC is a code indicating a specific system or component malfunction; however, it’s a starting point, not a definitive diagnosis. Always remember that a DTC points to a potential problem area, requiring further investigation.

The Innova system, alongside its manuals, emphasizes that DTCs should be used in conjunction with vehicle-specific service manual procedures. Never replace parts based solely on a DTC reading. Proper diagnosis involves verifying the code with testing, inspecting related components, and understanding the underlying system functionality. A single DTC can sometimes indicate multiple potential causes, making thorough investigation crucial for accurate and cost-effective repairs. Utilizing resources like the Innova website and forums can further aid in DTC interpretation.

Innova Resources & Support

Innova provides manuals, video tutorials, and active forums for easy support; no time-consuming account setups are needed to get started quickly.

Official Innova Website & Manuals

Innova’s official website serves as a central hub for accessing comprehensive resources to maximize your diagnostic tool’s potential. Users can find detailed product manuals directly on the site, offering step-by-step guidance on setup, operation, and troubleshooting. These manuals cover everything from initial device activation to interpreting diagnostic trouble codes (DTCs) and utilizing advanced features like ABS code reading on the 5210 model.

Beyond downloadable PDFs, Innova also provides access to a knowledge base filled with frequently asked questions, helpful articles, and technical support documentation. This ensures users can quickly resolve common issues and understand the intricacies of vehicle diagnostics. The website’s intuitive design makes navigating these resources straightforward, even for those new to automotive repair. Regularly checking the official website guarantees access to the latest updates, software downloads, and expanded support materials, keeping your Innova scanner performing optimally.

Video Tutorials for Beginners

Innova understands that navigating automotive diagnostics can be daunting, especially for beginners. To address this, they offer a robust library of video tutorials accessible through their official website and other online platforms. These videos provide visual, step-by-step demonstrations of how to use the 5210 and 5010 scanners effectively.

Tutorials cover essential functions like performing code retrieval procedures, understanding DTC definitions, and resetting check engine lights. They also demonstrate how to leverage the scanners’ user-friendly interface and ergonomic design, including utilizing the large buttons for easy operation. Innova’s video content simplifies complex processes, making DIY car diagnostics approachable for everyone. These resources complement the downloadable manuals, offering a multi-faceted learning experience and ensuring users can confidently tackle vehicle maintenance and repair tasks.

Innova Forums & Community Support

Innova fosters a vibrant online community through its dedicated forums, providing a platform for users to connect, share knowledge, and troubleshoot issues related to their diagnostic tools. This forum serves as a valuable resource for both novice and experienced users seeking assistance with code interpretation, vehicle-specific diagnostics, or scanner operation.

Members can access a wealth of information, including discussions on common DTCs, repair tips, and best practices for utilizing the 5210 and 5010 scanners. The community-driven support system complements the official Innova manuals and video tutorials, offering real-world insights and solutions from fellow enthusiasts. Users can post questions, share their experiences, and benefit from the collective expertise of the Innova user base, creating a collaborative learning environment.

eSpired Integration & Online Learning

eSpired delivers a fun and easy-to-use online Learning Management System (LMS) for students, while providing teachers and parents with assessment tools.

eSpired Learning Management System (LMS)

eSpired has meticulously developed a proprietary online Learning Management System (LMS) specifically designed to be both enjoyable and intuitive for students. This platform isn’t just about delivering information; it’s about fostering a positive learning experience. Simultaneously, eSpired recognizes the crucial role educators and parents play in a child’s development.

Therefore, the LMS is equipped with robust tools that empower them to effectively assess student progress and understanding. This dual focus – student engagement and parental/teacher oversight – sets eSpired apart. The system prioritizes a safe and secure online environment, ensuring a worry-free learning journey. It’s a comprehensive solution built to enhance educational outcomes and provide peace of mind.

Parent Account Setup & Management

eSpired understands the importance of a streamlined user experience, particularly for new users. If this is your initial visit to the platform, establishing a parent account is the first step. This process is designed to be straightforward and secure. You’ll need to utilize the email address associated with your recent purchase to initiate account creation.

Once your account is successfully set up, you’ll gain access to a dedicated management portal. This portal allows you to oversee your child’s learning journey, track their progress, and customize their educational experience. Managing multiple children is also simplified within the system, offering a centralized hub for all your family’s learning needs. It’s all about empowering parents!

Everbright Kids Magazine & Guides

As a special offer accompanying your purchase, your children can anticipate receiving the new Everbright Kids Magazine! This engaging publication is designed to make learning fun and accessible. Alongside the magazine, exclusive Kids Guides are released every 3-4 weeks, covering important and age-appropriate topics.

Each issue delves into a new subject, presented in a captivating and informative manner. These guides aren’t just supplemental materials; they’re designed to spark curiosity and encourage a lifelong love of learning. The content is carefully curated to align with educational principles, ensuring both entertainment and enrichment. Expect a special issue soon, packed with knowledge and fun activities for your kids!

Customer Support & Company Information

For assistance, contact Innova Customer Service via email at supportespired.com, or explore their Privacy Policy and Terms of Use online.

Contacting Innova Customer Service

Need help with your Innova diagnostic tool? Reaching out to their customer service team is straightforward. For subscribers looking to cancel their account, a dedicated option is readily available through their website. General inquiries and support requests can be efficiently directed to the Innova Customer Service team via email at supportespired.com.

Innova Electronics prioritizes customer satisfaction and aims to provide prompt and helpful assistance. Their website, innova.com, serves as a central hub for accessing support resources, including frequently asked questions, troubleshooting guides, and detailed product manuals.

Beyond email support, Innova also fosters a vibrant online community through forums where users can connect, share experiences, and find solutions to common issues. This collaborative environment complements the direct support channels, ensuring a comprehensive support experience for all Innova customers.

Innova’s Privacy Policy & Terms of Use

Innova Electronics is committed to protecting your privacy and ensuring a secure online experience. Their comprehensive Privacy Policy outlines how they collect, use, and safeguard your personal information when you interact with their products and services, including accessing manuals and utilizing online resources.

The Terms of Use govern your access to and use of the Innova website and associated platforms, such as eSpired. These terms detail your rights and responsibilities as a user, covering aspects like account creation, acceptable use, and intellectual property.

Transparency is key; Innova clearly articulates its data practices and provides users with control over their information. By using Innova products or services, you acknowledge and agree to abide by the outlined Privacy Policy and Terms of Use, ensuring a mutually respectful and secure relationship. Access these documents directly on their website.

About Innova Electronics & Consumer Brands

Innova Electronics Corporation stands as a leading innovator in automotive diagnostic tools and accessories, proudly holding the title of America’s No. 1 Diagnostic Tool Brand. For decades, they’ve empowered both professional mechanics and DIY enthusiasts with cutting-edge technology to understand and resolve vehicle issues efficiently.

Beyond diagnostic scanners like the 5210 and 5010, Innova boasts a diverse portfolio of consumer brands focused on automotive care and maintenance. This includes solutions for battery maintenance, jump starting, and tire inflation, all designed with user-friendliness and reliability in mind.

A commitment to education is central to Innova’s mission, exemplified by their eSpired platform. This integrated learning system provides resources for all ages, including the Everbright Kids Magazine, fostering a deeper understanding of automotive technology and empowering the next generation of mechanics. Innova consistently delivers quality and innovation.